The promise of Sodium-Ion Batteries

From left to right: Dr. J. Alberto Blázquez (CIDETEC Energy Storage, New Battery Technologies Team Leader), Ann-Kathrin Wurba (KIT-wbk), Julian Klemens (KIT-TFT), Dr. Iker Boyano (CIDETEC Energy Storage, Battery Manufacturing Pilot Line Team Leader), Elixabete Ayerbe (CIDETEC Energy Storage, Battery Modelling | Postmortem analysis Team Leader), Olatz Leonet (CIDETEC Energy Storage Researcher)

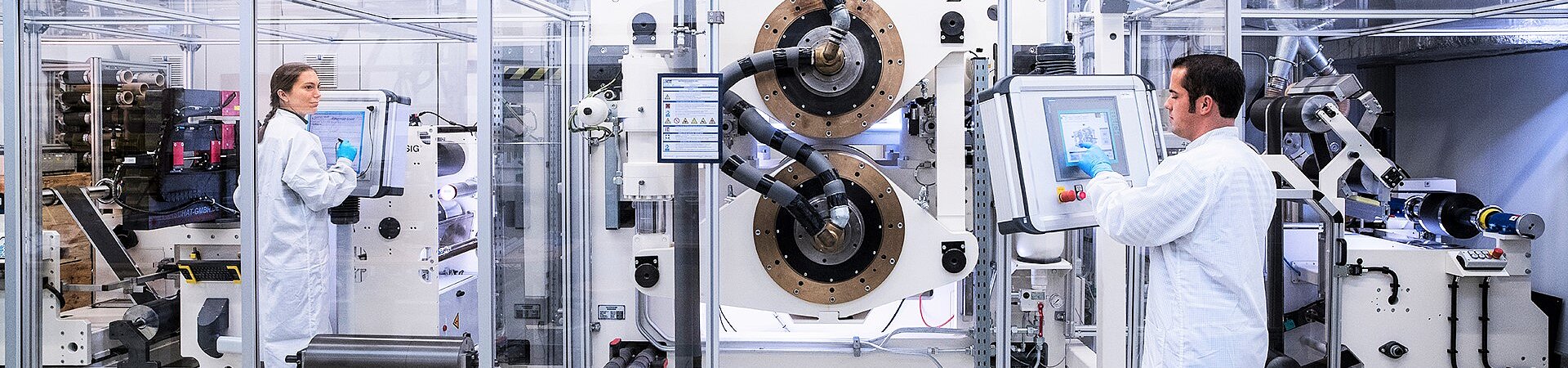

Julian Klemens (KIT-TFT) and Ann-Kathrin Wurba (KIT-wbk), both research associates of the POLiS - Cluster of Excellence, are exploring the challenges of large-scale production of sodium-ion batteries (SIB) during a three-month research stay at CIDETEC Energy Storage (Donostia-San Sebastián, Spain).

Sodium-ion batteries are considered one of the most promising post-lithium batteries. However, the producibility of the electrodes and batteries as well as the material processing challenges of potential electrode materials for anodes and cathodes are poorly understood. The challenges of large-scale production of SIB are being investigated in a research collaboration between the Karlsruhe Institute of Technology (KIT) and CIDETEC Energy Storage (Donostia-San Sebastián, Spain). In order to transfer their previous research results on electrode processing of SIB materials to a larger scale, two research associates of the Cluster of Excellence POLiS - Post Lithium Storage are on a research stay at CIDETEC. Research is being conducted along the entire production chain, from the active materials to electrode coating and drying to calendering and battery cell development. Materials developed within POLiS that can be produced on a pilot scale are used.

Julian Klemens from the group of Prof. Dr.-Ing. Dr. h. c. Wilhelm Schabel and Dr.-Ing. Philip Scharfer (Thin Film Technology) and Ann-Kathrin Wurba from the Institute of Production Science (wbk) in the research department Machines, Equipment and Process Automation directed by Prof. Dr.-Ing. Jürgen Fleischer are investigating together the structural optimization by multilayer coatings for specific adjustment of properties and faster production of battery electrodes as well as the influence of machine parameters in the calendering of new post-Li materials.

CIDETEC Energy Storage brings to this exchange the expertise of 15 years in the field of research and development of advanced battery technologies covering the full value chain from materials optimization to pilot scale production of taylored electrodes and cells for lithium, sodium and other chemistry based energy storage technologies. This activity is supported by the first-class battery testing laboratories, allowing to validate in house the performance of the technologies developed.