POLiS Lab

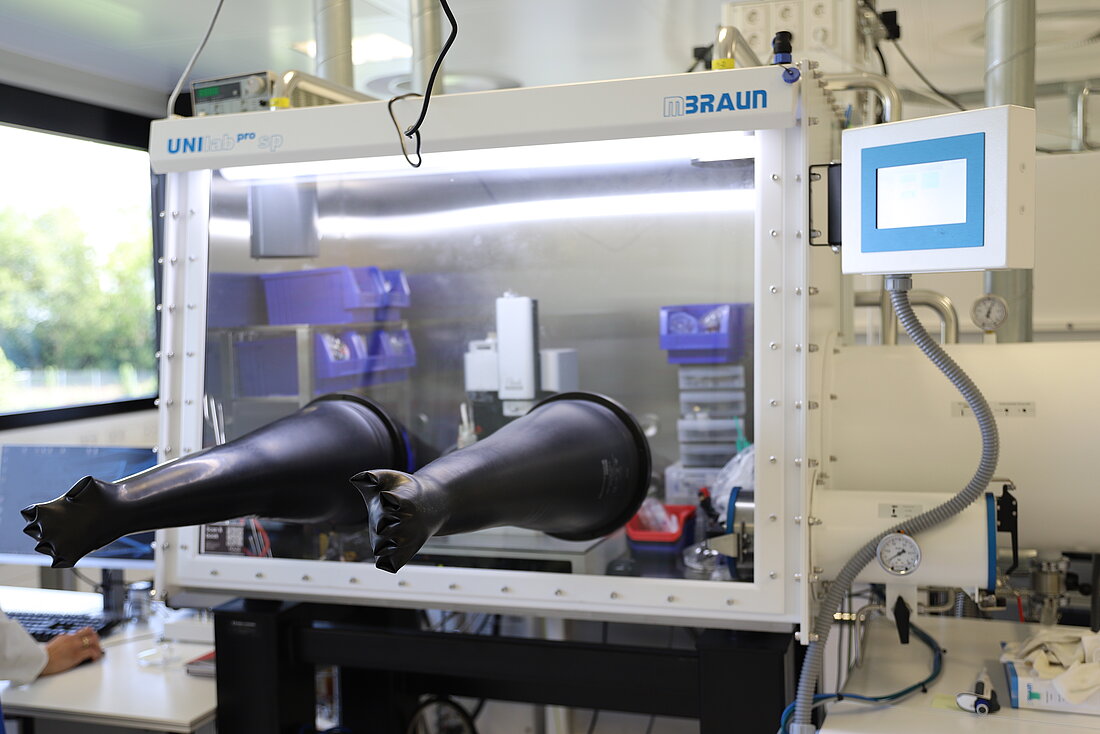

The Shared Facility in Ulm (LM16) combines physics and chemistry laboratories specialized for research in the field of energy storage and battery research. Main users are researchers of POLiS and associated projects. The physics and chemistry laboratories offer a wide selection of high-end devices that allows research from materials synthesis to characterization and electrochemical processes. The instruments and various gloveboxes are supplemented by the POLiS Materials Acceleration Platform (POLiS Map). With the Shared Facility, which is currently being expanded, we are aiming at establishing a reference laboratory for electrochemical energy storage beyond Lithium. Additional research infrastructure is available for POLiS researchers at Karlsruhe and Giessen. Together with the Shared Facility in Ulm, they form the POLiS Lab.

Selection of instruments in the Shared Facility in Ulm

AFM: Park NX10

AFM: Park NX10

The atomic force microscope is particularly valuable for battery research because, in addition to topography measurements in an Ar atmosphere, it can also be operated directly in the electrolyte in EC-AFM (Electrochemical Atomic Force Microscopy), allowing electrochemical processes on the material surface to be investigated in real time. This mode makes it possible to follow the changes in surface morphology during charging and discharging processes in detail and thus gain important insights into the degradation mechanisms of electrode materials. In addition, electrical conductivity can be measured at the nanoscale level, which is crucial for understanding and optimizing battery performance. The Park NX10's ability to analyze the mechanical properties of materials under electrochemical conditions supports the development of more robust and durable battery materials. In SECCM mode, the device can locally investigate electrochemical reactions using tiny liquid droplets as electrodes, allowing precise analysis of electrochemical activity at specific surface areas. In addition, the device can be used in AFM-SECM (Scanning Electrochemical Microscopy) mode, which enables the simultaneous analysis of topographical and electrochemical properties at the nanoscale level. This combination makes it possible to record the interactions between the electrical activity and the surface structure of battery materials in detail.

Battery Cycler: Biologic BCS and MPG

Battery Cycler: Biologic BCS and MPG

The Biologic battery cycler is particularly important for battery research as it can perform precise and repeatable charge and discharge cycles of batteries to evaluate battery performance and life under realistic conditions. With its ability to program different charge and discharge profiles, different operating conditions can be simulated to test the behavior and stability of the batteries. The device provides detailed data on capacity, efficiency and energy discharge, which is essential for optimizing battery materials and designs. In addition, the battery cycler enables long-term studies to be carried out to investigate the effects of cycling and environmental conditions on battery performance over extended periods of time. The precise control and monitoring of test conditions contribute to the accurate assessment of battery quality and reliability, which is crucial for the development of high-performance and long-lasting energy storage systems.

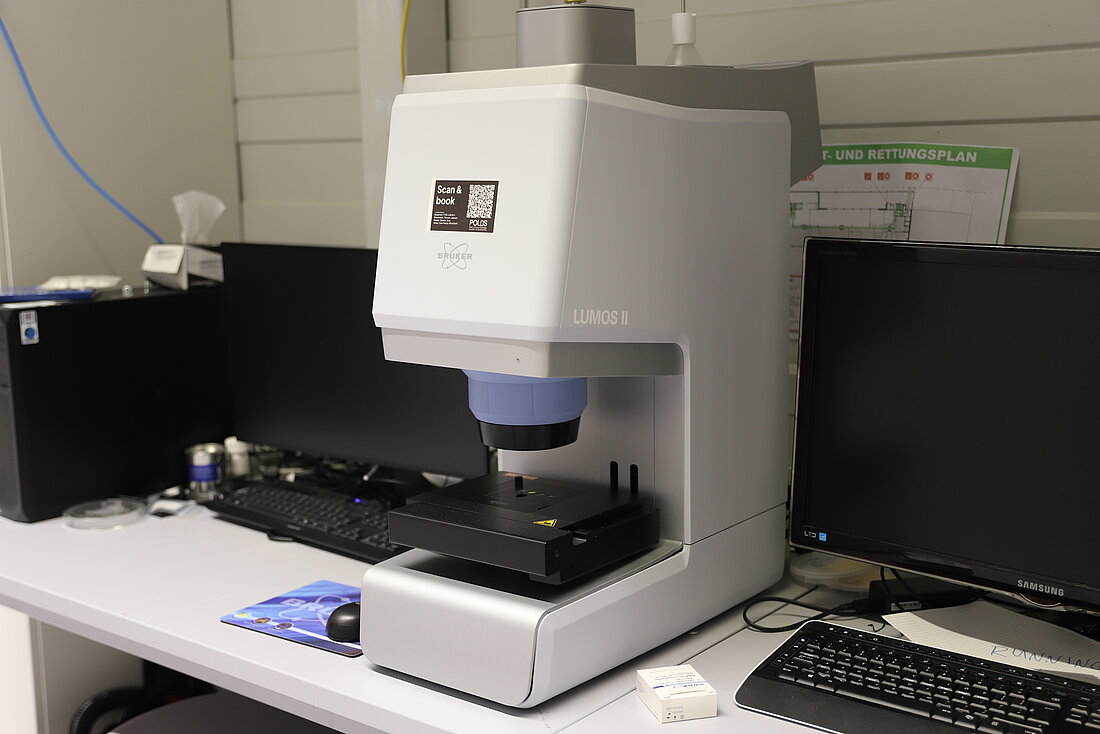

FTIR-Microscope: Bruker LUMOS II

FTIR-Microscope: Bruker LUMOS II

The FT-IR microscope analyzes the chemical composition of materials at the microscopic level by recording infrared spectra of small sample areas. This enables the identification of specific chemical bonds and functional groups in electrode materials and electrolytes, which is crucial for understanding chemical reactions and material changes during the battery cycle. With its high spatial resolution, local differences in material structure and composition can be detected, which can have an impact on battery performance. In addition, the FT-IR microscope offers the possibility to detect the formation of unwanted reaction products or impurities in the battery materials, which helps to improve the efficiency and lifetime of batteries.

Physiosorption: 3P BET

Physiosorption: 3P BET

The BET physisorption device measures the specific surface area and porosity of materials, which is crucial for the optimization of electrode materials. By determining the specific surface area, it is possible to understand how much reaction area is available for the electrochemical processes, which directly influences the performance and efficiency of the battery. The device allows the pore size distribution to be analyzed, which is of great importance when evaluating the accessibility and transportability of electrolytes within the electrodes. With the data obtained by BET, the material properties can be better matched to the requirements of batteries in order to improve charging and discharging performance. In addition, the physisorption device helps to monitor structural changes in the materials that can occur during battery cycles, thus enabling targeted material optimization.

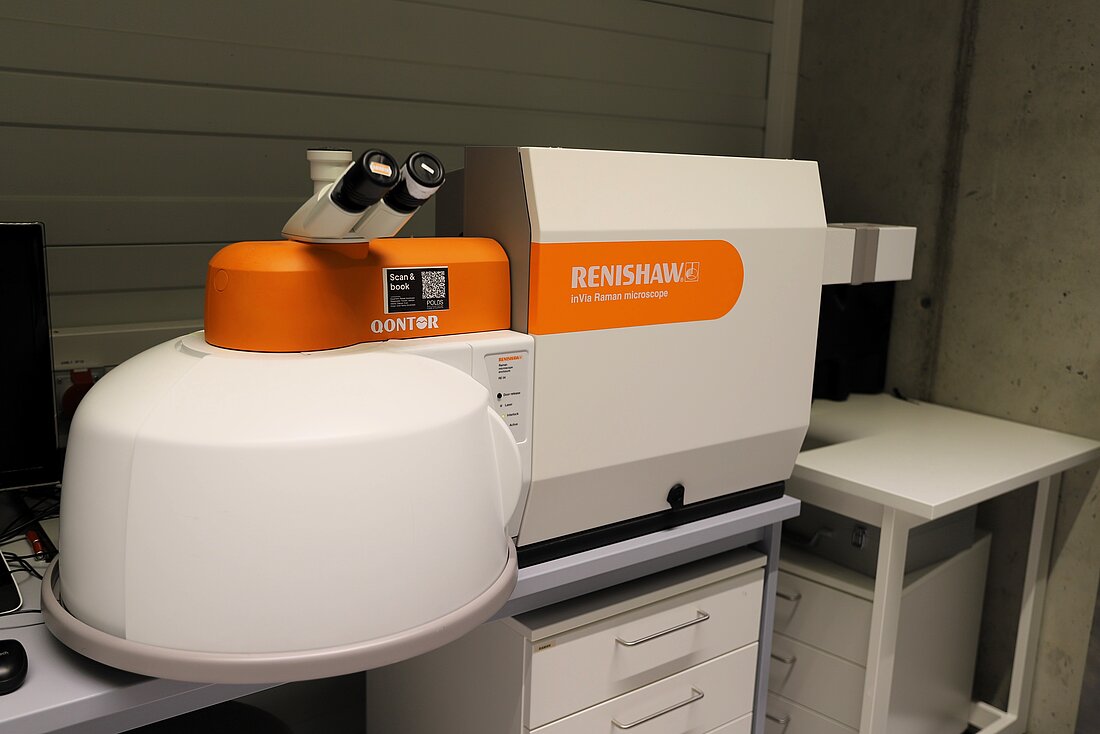

Raman Microscope: Renishaw inVia Qontor

Raman Microscope: Renishaw inVia Qontor

A Raman spectrometer is used to measure the inelastic scattering of light, known as Raman scattering, on molecules. This measurement provides information about the vibrational, rotational and other low-energy modes of the molecules in a sample. Essentially, a Raman spectrometer detects. These differences reflect the characteristic vibrations of the chemical bonds, allowing the chemical composition, molecular structures, crystallinity and phases of the materials to be identified. The chemical composition of battery materials is analyzed non-invasively at the microscopic level by measuring the specific energy differences between incident light and the scattered light caused by interactions with the molecular bonds. This enables the identification of phases and chemical changes in electrode materials during charging and discharging processes. Due to the high spatial resolution, local differences in material composition and structure can be detected, which contributes to the optimization of battery performance. The device can also be used to investigate reaction products and impurities that affect the efficiency and service life of batteries. In addition, Raman spectroscopy allows amorphous and crystalline phases to be analyzed, providing comprehensive insights into material development for more efficient energy storage systems.

RAS: Laytec EpiRAS

RAS: Laytec EpiRAS

Reflectance Difference Spectroscopy (RAS) is particularly useful for battery research as it provides high-precision information about the surface structure and chemical states of electrode materials. It makes it possible to detect surface changes and reaction products on the nanoscale that occur during charging and discharging processes and thus to monitor material stability and performance. RAS can also detect the formation of surface films and coatings that could affect battery performance, helping to improve material properties. In addition, the method provides insights into the interactions between the electrode materials and electrolytes, which is crucial for the design of more efficient battery constructions.

SECM: Sensolytics SECM

SECM: Sensolytics SECM

The SECM (Scanning Electrochemical Microscope) enables electrochemical measurements at the microscopic level to detect local differences in battery performance. The ability to monitor electrochemical reactions in real time provides detailed insights into the reaction dynamics and degradation mechanisms within the battery materials. The device allows the investigation of surface and interfacial processes that are critical to battery efficiency and stability. With the SECM, specific areas within the battery can be investigated to identify problems such as inhomogeneous reactions or local short circuits. These precise and localized measurements contribute to the improvement of battery design and the development of more durable and efficient energy storage systems.

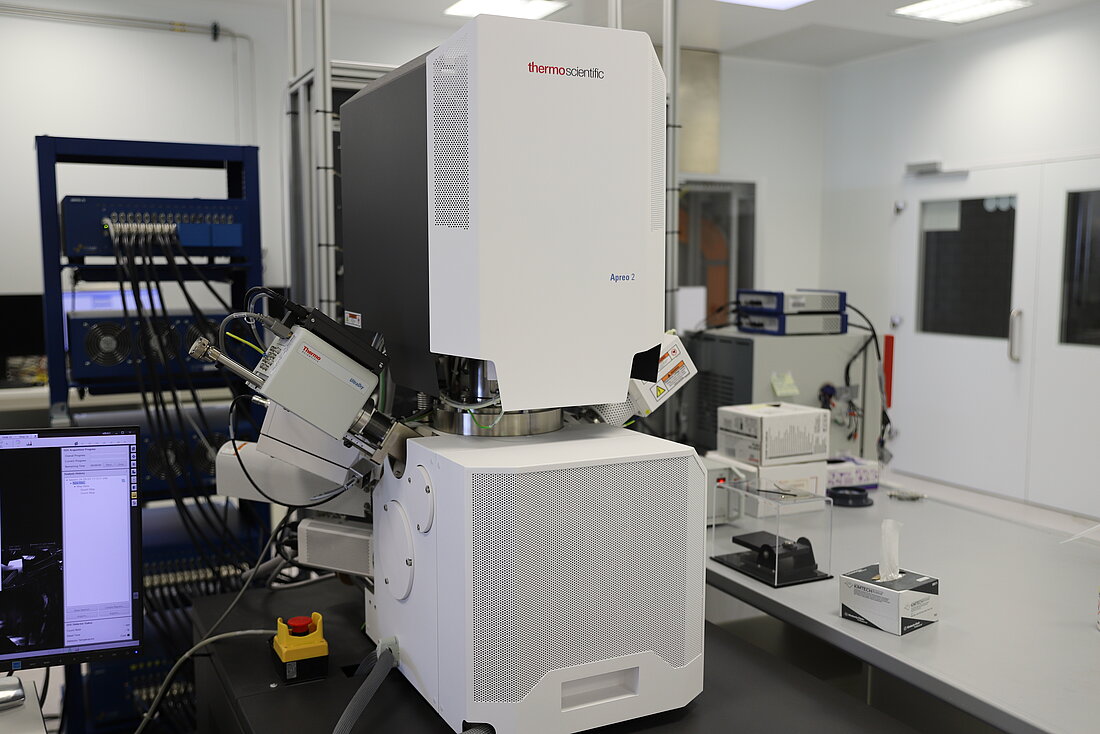

SEM: ThemoFisher Scientific Apreo 2s

SEM: ThemoFisher Scientific Apreo 2s

The scanning electron microscope (SEM) provides high-resolution images of the surface structure of battery materials, which is essential for understanding material defects and degradation mechanisms. With its ability to capture both topographical and chemical information through integrated EDX (energy dispersive X-ray spectroscopy) analysis, it enables precise examination of elemental distribution in electrodes and electrolytes. The device can also analyze nanoscale structures such as particle sizes and porosities, which have a direct influence on the performance and service life of batteries. In addition, the Apreo 2S offers the possibility to characterize samples without exposure to air by means of an inert gas transfer, for example to determine changes before and after charging and discharging cycles. With these comprehensive analysis capabilities, it contributes significantly to the development and optimization of advanced battery materials.

XPS: SPECS EnviroESCA

XPS: SPECS EnviroESCA

High-resolution X-ray photoelectron spectroscopy (XPS) provides detailed analysis of the chemical composition and bonding states on the surface of battery materials. This technique makes it possible to precisely monitor the chemical changes and reaction mechanisms on the surface of electrodes and electrolytes, which is crucial for understanding degradation processes and performance degradation. The NAPXPS can be used to identify specific chemical conditions and contaminations that can negatively affect the efficiency and life of batteries. The device also provides information on the distribution of chemical elements and their bonding environments, which helps in the development of new materials and the optimization of existing battery designs. The ability to perform measurements at elevated pressures (near ambient pressure) provides deeper insights into material chemistry.

XRD: Stoe StadiP (Mo, Ag)

XRD: Stoe StadiP (Mo, Ag)

The XRD analyzes the crystalline structure of battery materials and thus provides important information about phase transitions and material stability. It enables the identification and quantification of crystalline phases, which is essential for understanding electrochemical properties and optimizing battery performance. With its ability to perform in-operando measurements during the charging and discharging process, the device can monitor changes in the material structure in real time. This helps to better understand degradation mechanisms and structural changes that affect battery life. In addition, the high resolution and sensitivity of the XRD allows the investigation of nanostructured materials, which are becoming increasingly important in modern batteries.

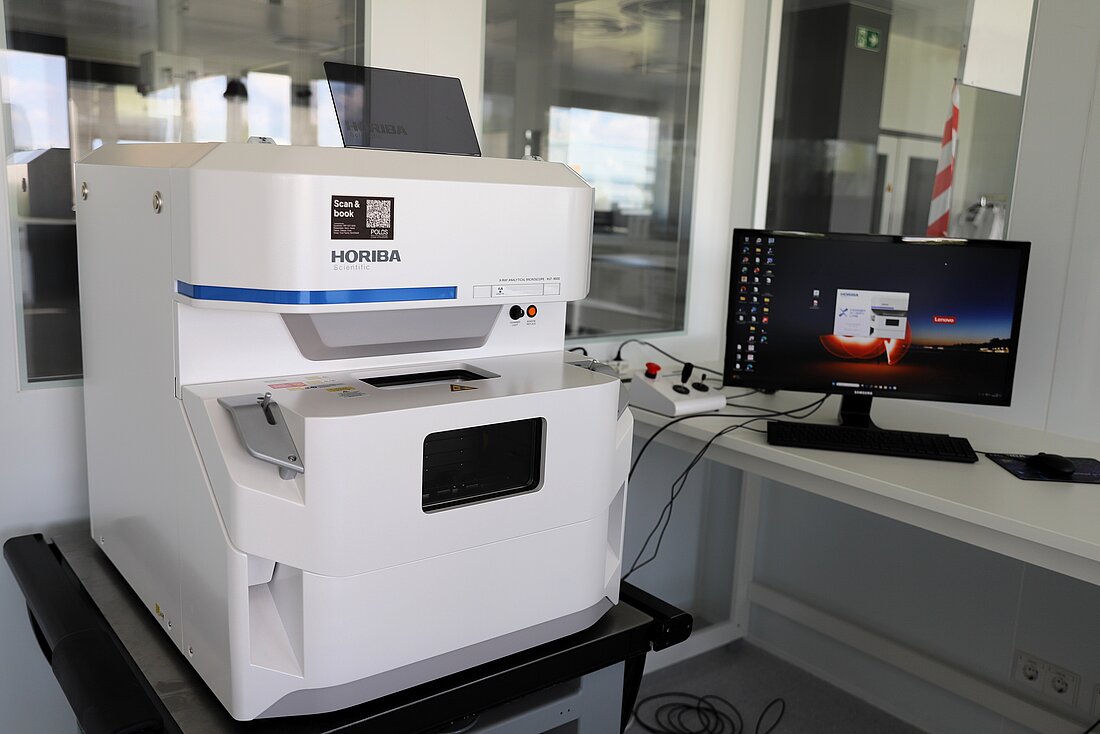

XRF: Horiba XGT-9000

XRF: Horiba XGT-9000

The Horiba XGT-9000 analyzes the chemical composition of materials without destroying the samples and enables fast and detailed investigations of the element distribution in battery materials, which is crucial for optimizing performance and service life. The device can analyze microscopic areas, which is a great advantage when investigating defects and degradation mechanisms in battery cells. Thanks to its high resolution and sensitivity, trace elements and impurities that could impair battery performance can also be reliably detected. In addition, the non-invasive analysis method allows repeated measurements on the same sample, which is essential for long-term studies.

Further instruments that can be found in the Shared Facility in Ulm

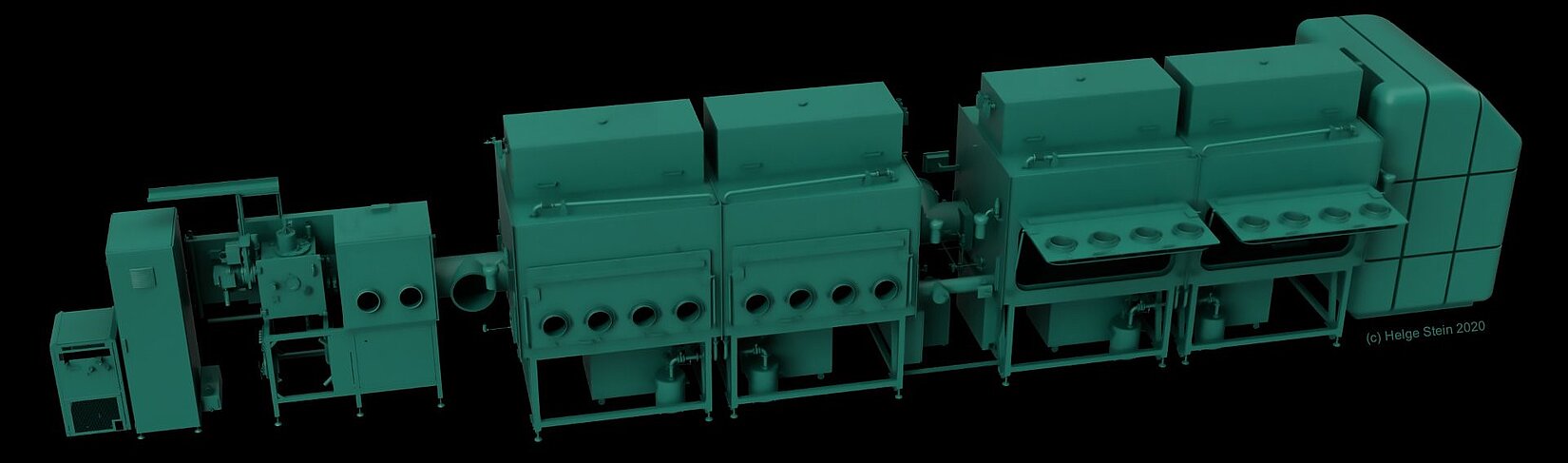

POLiS MAP

Helge Stein / HIU

Helge Stein / HIU

This platform combines various experimental and analysis techniques integrating them in extensively automated and configurable workflows. This allows the platform to cover the tasks of a conventional laboratory for battery research while providing a common interface for all its associated instruments and methods and enables for example machine learning algorithms to interact with the platform via FINALES or HELAO. The high degree of automation of the individual modules of the setup enables autonomous research campaigns. The modules connected to the platform can also be used independently. We demonstrated, that individual modules of the platform and large parts of the platform can be integrated in Materials Acceleration Platforms (MAPs) that include institutions and their respective infrastructure located in different countries. This fosters tighter collaborations among research institutes and enables researchers to use instruments and methods that might normally not be easily accessible to them.

The hardware of the POLiS MAP comprises two large nitrogen-filled gloveboxes that are connected via two antechambers. In the gloveboxes several modules are hosted offering a variety of capabilities to the platform. Further instruments are located external to the glovebox and are connected to it via tubing or antechambers.

Software frameworks

FINALES

The Fast INtention-Agnostic LEarning Server (FINALES) software framework provides a central hub for communication between different tenants. A tenant is a unit connected to FINALES that may be a piece of hardware, a software, a human researcher or even a whole laboratory. This means, that FINALES can serve as a basis for MAPs. FINALES provides the possibility for tenants to post requests asking for certain data to be provided. Such a request may be picked up by another tenant that is capable of running an experiment, executing an algorithm, querying a model, etc. to obtain the requested data that it subsequently posts back to FINALES as a result. FINALES itself serves as a purely passive marketplace and does not trigger any actions. It does not impose requirements on the internal procedures of the tenants and is therefore facile to connect versatile tenants to FINALES. Also, by leaving the control of the respective processes with the tenants, decentralized MAPs become feasible. Also, tenants can be temporarily disconnected from the MAP and reconnected at a later point in time without disrupting the remaining MAP. FINALES can also be run within an institution to enable external collaborators to request the laboratory’s services using FINALES as an interface.

HELAO

The Hierarchical Experimental Laboratory Automation and Orchestration (HELAO) framework orchestrates different instruments within a laboratory. Researchers can define experiments as a sequence of calls to actions that are implemented in HELAO. These actions are in turn calling lower-level functions on a driver level. An example could be, that a researcher wants a probe head to be moved to a specific position on a sample. For this, the respective action would be called that in turn calls the necessary driver level functions for moving a motor. Since device-specific calls are encapsulated in the driver functions and actions are defined in a more general fashion, actions may be reused for different setups by only exchanging the driver layer.

HELAO collects metadata during all its processes and therefore enables traceability and comprehensive information about executed process steps. Furthermore, experimental procedures controlled by HELAO can be augmented with machine learning algorithms to achieve autonomously operating clusters of instruments.

Hardware modules

ASAB

The setup for the Autonomous Synthesis and Analysis of Battery Electrolytes (ASAB) automatically formulates liquid electrolytes based on stock solutions and analyses them using nuclear magnetic resonance (NMR) spectroscopy, Electrochemical Impedance Spectroscopy (EIS), densimetry or viscometry. It can further output the prepared solutions so they can be used for example to assemble coin cells using the Automatic Battery Assembly System (AutoBASS). Automatic triggers for all instruments except the NMR device are implemented. ASAB utilizes the Modular and Autonomous Data Analysis Platform (MADAP) to automatically analyze EIS results and obtain the ionic conductivity of the electrolytes, which is an important property of electrolytes in battery applications. Due to this high degree of automation, the ASAB system can be integrated in fully autonomous research campaigns centered around FINALES requiring only minor human intervention.

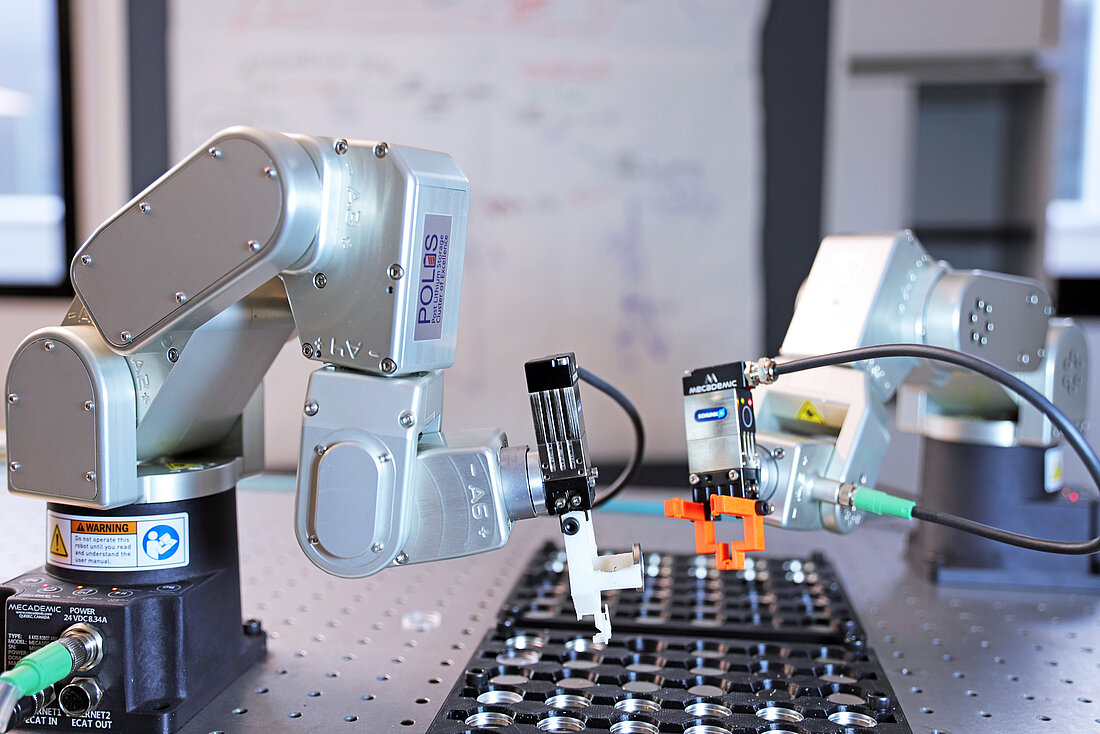

AutoBASS

The Automatic Battery ASsembly System (AutoBASS) can fully automatically assemble coin cells with high reproducibility and minimal human intervention. The system is equipped with three robotic arms that are used to pick and place the cell components, add the electrolyte using a pipetting tip, and place the cell in the crimper or collect it from there, respectively. AutoBASS further has two cameras. One is attached to the robot arm and a second one is positioned next to the pole where the cells are assembled. These cameras are used to correct for off-center gripping using an edge detection algorithm to improve the stacking accuracy. The photos taken by the cameras are stored for documentation of the assembly process. AutoBASS was also included in a FINALES-based MAP.

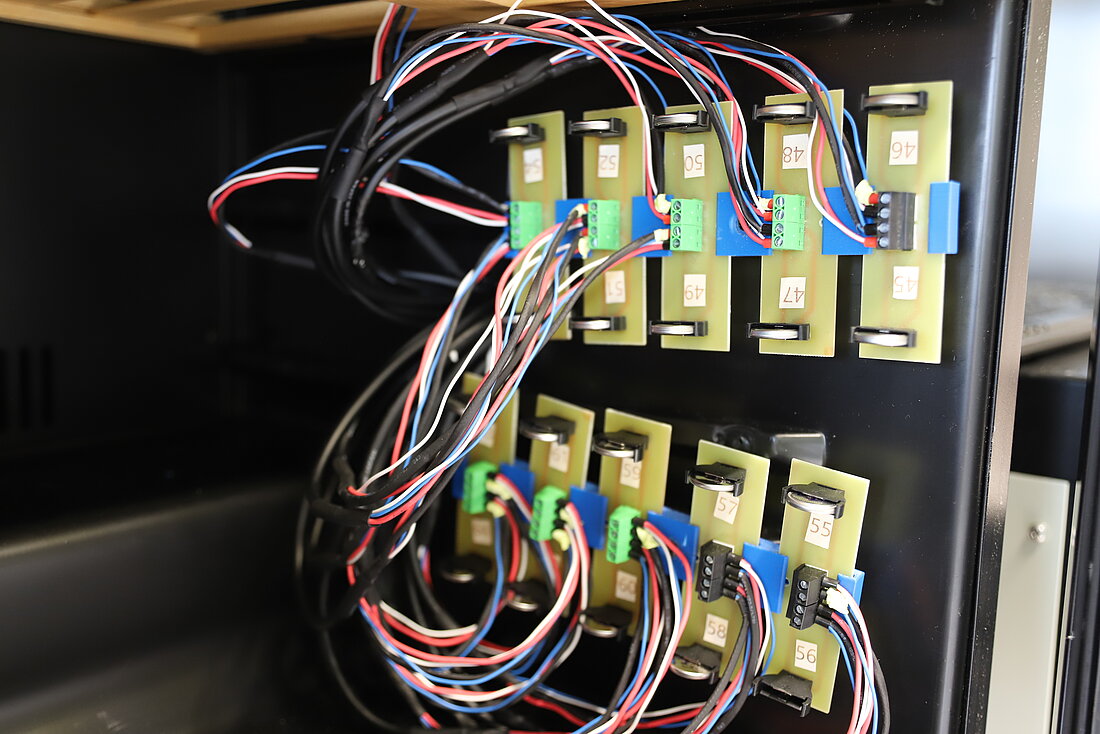

Cycler

Once assembled, the coin cells are transferred out of the glovebox and mounted in the channels of the battery cycler. This device charges and discharges the battery cells according to a protocol that is provided by a researcher. Except for the mounting of the cells and the definition of the cycling procedure, the operation of this machine is also fully automated and the data can even be analyzed automatically. This enabled inclusion of this device as part of a MAP based on FINALES.

HITS

The setup for High-Throughput Spectroscopy (HITS) can perform spectroscopic analysis using Fourier-Transform Infrared (FTIR) and Raman spectroscopy. This device utilizes a sample stage movable in x, y, and z direction to raster over a sample. Samples may be for example wafers coated with electrode material and tested using the SDC (see below). A transformation between the coordinate systems of HITS and the SDC is implemented to allow the correlation of the results for every sample position.

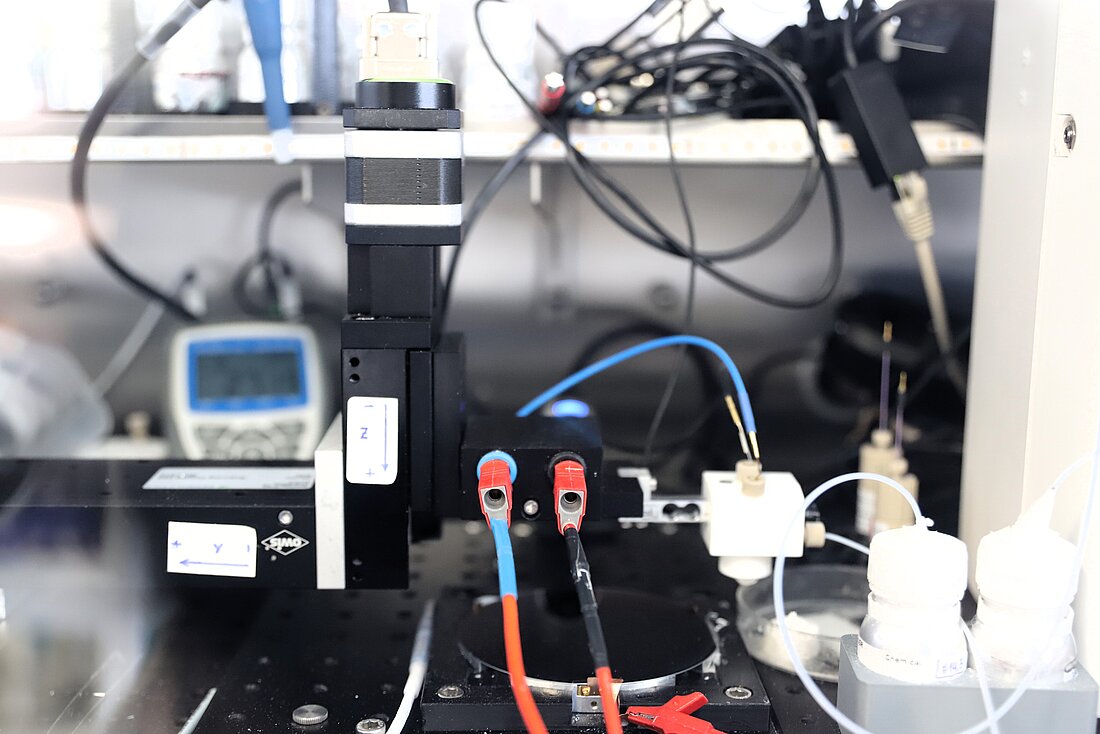

SDC

The Scanning Droplet Cell (SDC) consists of a movable probe head attached to a force sensor. The probe head is equipped with a reference electrode, a counter electrode and a tube to provide electrolyte. The electrodes are connected to a potentiostat. The probe head is lifted up from the sample, moved to a sample position and lowered down to establish contact with the sample by a set of spindles and motors. Once the probe head is lowered, electrolyte is supplied to the measuring volume where it contacts the sample, the reference electrode and the counter electrode. In this setup, the sample serves as the working electrode. The electrolyte composition may be varied and EIS, cyclic voltammetry (CV) or other electrochemical tests feasible in such a three-electrode setup can be performed. The SDC allows to stop e.g. CV experiments at various points in time and subsequent analysis of the results can yield information about the SEI or CEI formed on the sample, which are critical for the performance of batteries.

Research facilities in Karlsruhe and Giessen

At Karlsruhe Institute of Technology (KIT)

Battery Technology Center (BATEC) - Scale-up and processing; large-format cells

Karlsruhe Nano Micro Facility (KNMFi) - Spectroscopy and microscopy

At Justus Liebig University Giessen (JLU)

The Center for Materials Research (ZfM) - Materials analysis

GC-ElMaR - Electrochemical characterisation, Solid State Ionics